Chamber Roundtable Explores International Paper’s Global and Local Impact

On October 28, the Springfield Area Chamber of Commerce hosted a Roundtable + Tour at International Paper’s Springfield Containerboard Mill on 42nd Street in Springfield. With attendance capped at 35 participants, the exclusive program offered members a rare inside look at one of Lane County’s largest employers and economic anchors.

To begin the program, the Springfield Chamber’s Senior Director of Advocacy & Economic Development, Paige Walters, introduced International Paper Mill Manager Matt Vaughn.

Mr. Vaughn, joined by several other IP representatives, offered a casual and conversational presentation about the global company’s past, present, and future. Mr. Vaughn was followed by Senior Regional Manager Cynthia Leon, who laid out the current regulatory climate for IP. Chamber members had many interesting and topical questions along the way.

“The [economic] impact of the Springfield facility cannot be overstated.”

– Matt Vaughn, Mill Manager, International Paper

A Legacy of Innovation and Local Commitment

Matt Vaughn began his presentation with a brief history of IP. Founded in the late 1800s as a consortium of newsprint mills, International Paper (IP) has evolved into a global leader in sustainable, fiber-based packaging. The Springfield mill exemplifies that legacy, producing containerboard that becomes the corrugated boxes used by household names like Amazon and Costco. The Springfield plant is a union facility that employs nearly 300 workers, and this number doesn’t include contractors like trucking companies and recyclers, all of whom are vital to IP’s processes. The mill is also one of Lane County’s largest taxpayers.

Investing in People

From utility operations to machine tenders, all IP employees receive in-house training and highly competitive wages. The mill’s precision maintenance and associate training programs ensure employees can build long-term, high-skill careers right here in Springfield. Importantly, nearly all of IP’s workforce comes from the local community, reinforcing the company’s role as both an economic driver and a career pipeline for residents of Lane County.

Innovation in Sustainability

During the tour, attendees learned how the IP integrated mill turns wood chips and recycled fibers into paper rolls, a process that combines century-old science with modern efficiency. The operation is nearly 100% self-contained, featuring a “powerhouse” that generates its own steam and electricity, and a closed-loop chemical recovery cycle that minimizes waste.

Water stewardship was another highlight. Over the past five years, the mill has reduced water usage by 20%, while maintaining the same paper output. IP draws water from the McKenzie River, treats it at an EPA- and DEQ-approved facility, and returns 90% back to the river.

A Call for Balance in Oregon’s Energy Future

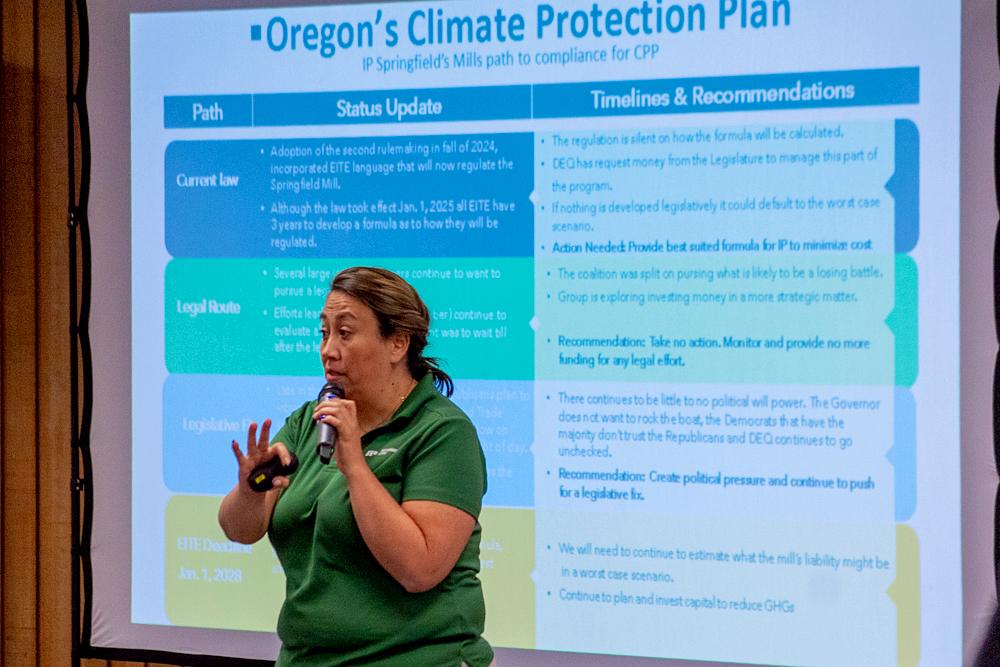

Attendees then heard from Cynthia Leon, IP’s Government Relations Manager, who discussed the ongoing uncertainty surrounding Oregon’s Climate Protection Plan (CPP) and its potential implications for energy-intensive industries.

“We want to be regulated, but we also want to be part of the conversation to find solutions that keep jobs and investment in Oregon.”

– Cynthia Leon, Senior Regional Manager, International Paper

While IP has made major strides in environmental protections – operating primarily on biomass and recovered chemicals – the company remains concerned about disproportionate regulatory costs that could threaten its ability to remain competitive in Oregon.

With Oregon’s DEQ still developing its formula for energy-intensive, trade-exposed industries, the outcome could have significant consequences for businesses like International Paper. The Springfield Chamber has been tracking this issue during the past two State legislative sessions. As talks about the Climate Protection Program and Cap and Trade Programs progress further, member businesses will be notified of opportunities to weigh in on the impact to your business. Visit the Springfield Chamber’s Business Advocacy webpage for more information about how to stay informed and engaged.

Mill Tour: The End Product

After presentations, attendees grabbed their PPE and followed Mr. Vaughn out to the active mill, which presses and dries wood pulp into paper 24 hours a day. The tour wound through a vast series of metal grate and concrete walkways, within mere feet of workers seeing the wood pulp though a rigorous process of pressure and dehydration. On the other side, workers manned a machine called a “winder” which then cut the 50-ton rolls into smaller units at the rate of 6,500 feet per minute. Mr. Vaughn and other employees pointed out some of the features of the plant and answered questions throughout the tour.

A Global Company with Local Roots

International Paper’s story is one of resilience, innovation, and community stewardship. As part of a 125-year-old company with operations around the world, the Springfield mill continues to demonstrate what responsible manufacturing looks like: sustaining livelihoods, supporting environmental progress, and strengthening the local economy.

The Chamber thanks International Paper for hosting this informative and inspiring Roundtable + Tour, and for continuing to invest in the people and communities of Springfield.

Discover more from Springfield Bottom Line

Subscribe to get the latest posts sent to your email.